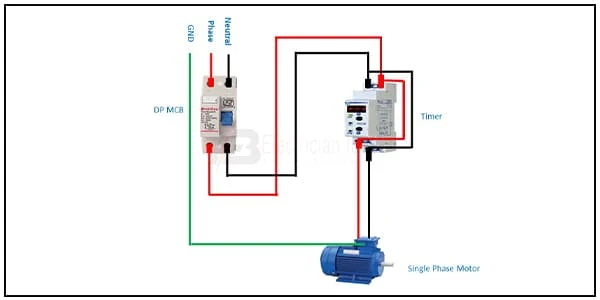

Automatic Timer switch for Water Pump

This diagram shows the Timer connection with Water Pump. When it's required to control the power of a pump, here the most effective and common option is to use a pump timer switch. A pump timer switch automates your water pumping system and can be determining when the pump starts and stops. The switch can be programmed to turn on at set times throughout the whole day or night, allowing you to save energy. In this circuit diagram, we connect a single-phase motor with a Timer. The timer power source is connected from DP MCB ( Double Pole Miniature Circuit Breaker).

Images of Automatic Timer switch for Water Pump wiring

Components Need for this Project:

You can get the components from any of the sites below:

Read Also:

Components used to make the Timer switch for Pump:

01. Single Phase Motor

|

| Fig 2: Single Phase Motor |

02. DP MCB

|

| Fig 3: DP MCB |

03. Timer

|

| Fig 4: Timer |

Thank You for visiting the website. Keep visiting for more Updates

Frequently Asked Questions

When it's required to control the power supply to a pump, one of the most efficient options is to use a pump timer switch. A pump timer automates your water pumping system, determining when the pump starts or stops. The switch can be programmed to turn on at set times throughout the day and night, allowing you to save energy.

Here's an automatic water pump controller circuit diagram that controls the water pump motor. The motor gets automatically switched on if the water in the overhead tank (OHT) falls below of the lower limit. Similarly, it gets switched off tank is filled up.

With timer operation, the Time Switch controls the output according and the set ON or OFF times. With pulse-output operation, the Time Switch outputs a pulse of the specified time width at the set ON time. The power supply was turned ON by a Time Switch.

A simple way of controlling pumps is the use of inverters, converters, or frequency inverters. The rotational speed was varied by controlling the amplitude, or by changing the frequency.

But in most instances, water pumps fail because of the shaft leaks. Water pumps also could be the victim of cavitation inside the coolant system. The movement of the impeller blades in the coolant could create the flow that generates cavitation. Superheated vapor pressure could occur and eat away and the metal.

Post a Comment

Do leave your comments